24 Hr Emergency Response

800-377-3648

10,000 Environmental Remediations Since 1975

Remtech © 2024

| CAREERS |

| Contact Us

Diesel Bioremediation on Mainline Track with HC-2000 | Hiram, GA

Location: Northwestern Georgia

Client: Major Railroad

Contract Amount: $42,000

PROBLEM

A locomotive caught fire on a major railroad’s super elevated mainline track. An estimated 100-gallons of diesel fuel were released along a 100 foot track section.

SOLUTION

Remtech designed and installed a solar/battery powered mist system to supply oxygen and water during the remediation process to maintain a 75% water field holding capacity.

Track ballast served as a biological trickling filter. HC-2000 was applied during the first three days of treatment followed by weekly HC-2000 applications to accelerate the native fungi and bacteria biodegradation process. Air sparge tips were driven into the ballast to increase oxygen levels. A battery driven compressor was utilized to supply air through the sparge tips.

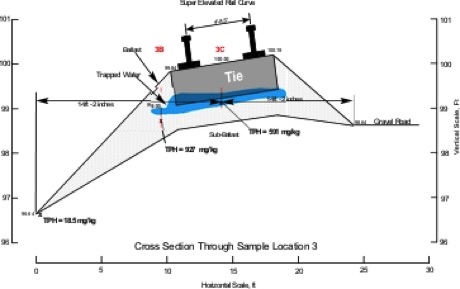

Four (4) sampling points were monitored over an 118 day treatment period. Average TPH concentrations were reduced 90%.TPH concentrations at the toe of ballast next to the drainage ditch was recorded at 18.5 mg/kg at the end of the project indicating that petroleum hydrocarbons were being degraded within the railroad ROW.

COST/BENEFITS

Track time interruption to excavate and replace this mainline track section would have been cost-prohibitive.

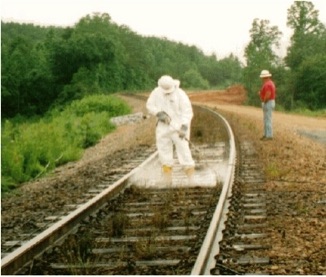

HC-2000 Application on Track Bed

Mist application Supplies Water & Oxygen to Site

Solar Powered Auto Mist System Provides Oxygen & Moisture to Track Bed

Track Cross-Section of HC-2000 Diesel Degradation