24 Hr Emergency Response

800-377-3648

10,000 Environmental Remediations Since 1975

Remtech © 2024

| CAREERS |

| Contact Us

Track Siding Diesel Bioremediation at Rail Crossing at-grade Collision Site with HC-2000 | Smarr, GA

Location: South Georgia

Client: Major Railroad

Contract Amount: $65,000 (50% of Costs Associated with Water Well within 500 ft from release)

PROBLEM

An at-grade crossing collision on a track siding with a train and fuel truck released over 1,000-gallons of diesel fuel over a track distance of 175 feet.

SOLUTION

The fuel saturated asphalt road and sub-grade were removed and replaced. An initial application of HC-2000 and water were used to flush the mobile phase out of the ballast. A total of twelve (12) applications of HC-2000 (205 gallons) were made over a twelve (12) month period. Degradation monitoring continued for a total of 14 months.

A water well was located less than 500 ft downgradient from the release. A monitoring well was installed immediately downgradient from the tracks to ensure that the water well was not impacted.

No contaminates were detected in the water well. Groundwater Polycyclic Aromatic Hydrocarbons (PAHs), BTEX, and (DROs) were degraded below detection limits in the monitoring well.

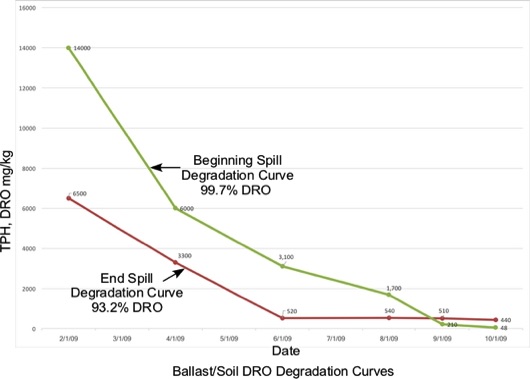

Diesel Range Organics (DRO) ballast/soil concentrations were reduced by an average of 96.5%.

COST/BENEFITS

The track ballast was treated without taking the track out of service and saved the railroad thousands of dollars in saved track time alone. 50% of the costs associated with this project was due to demonstrating that this release did not impact the well.

At-Grade Vehicle Collision Releases Diesel Fuel

HC-2000 Application on Track Diesel Spill

Track after Treatment with HC-2000

HC-2000 Soil/Ballast Diesel Degradation Curves

(DRO Reduced Average of 96.5%)