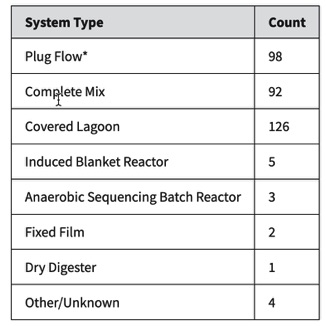

One of the 10 projects reportely approved for construction was still submitting revised permit information in early 2022. This translates to only 9 under construction. California applications for projects have been largely restricted to covered lagoons since 2019. At the 2022 BIOGAS AMERICAS conference in late May, 55 projects were celebrated by ABC for their longevity in operation, with 41 projects recognized for more than 10 years in operation and 14 projects operating for five years or more. DVO, ConAgra, CDM Smith and CH4 Biogas were acknowledged for each having a digester project in operation for more than 10 years. Cumulatively, these 55 systems have provided nearly 700 years of non-stop service.

Reviews of more elaborate plug flow mixed and heated reactors were found to be only 30% efficient in 2022 even with heat sources from an adjacent ethanol plant was available. Site Source. One of the largest plug flow reactor companies bankrupted a farmer and was forced to pay attorney fees incurred by the farmer. Renewable manure energy sources are not economicaly feasible without renewable energy credits. A major issue is that government subsidized renewalble energy credits are only paid when renewable energy is produced. Failed designs, inadequate feedstocks with adequate energy, untrained operations, unanticipated high energy costs, equipment replacement due to corrosive nature of manure, and lack of understanding and estimating permitting processes have been largely responsible to failed projects.

Kraig Westerbeek, vice president of Smithfield Renewables for Smithfield Foods, says that “along with our JV Partners, we have completed construction and are currently operating several of the largest manure-to-energy projects in the U.S.”

The bulk of the California money pouring into the technology is benefiting two companies, Maas Energy Works and California Bioenergy, that rely on natural gas revenue to survive. Roughly 90 percent of the more than $350 million in incentives disbursed for digester projects to date has made its way to projects headed by either of the two companies. CalBio has also teamed with Land O’ Lakes, an agribusiness cooperative that is one of the largest producers of dairy products in the United States, with $16 billion in net sales in 2021. Land O’ Lakes has spent over $140,000 lobbying the California Department of Food and Agriculture, which manages the state’s digester program, and the California Air Resources Board regarding methane reduction programs and methane regulations. A spokesperson for Land O’ Lakes said in an email that the company has asked legislators to provide grant funding to farms to drive the adoption of digesters.

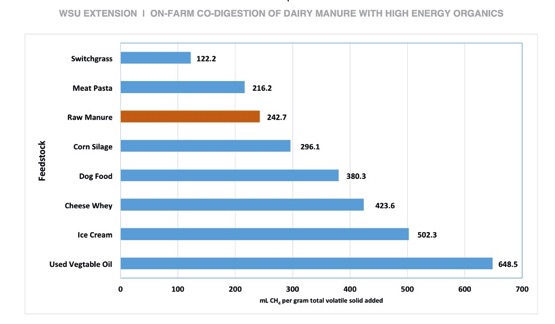

Dairy manure has a low methane production rate compaired to other waste streams that requires large dairy herds (3000+) and in many cases requires cogeneration of additional higher energy waste streams.

Selecting a dairy manure project for biomethane production conversion into renewable natural gas requires several factors to ensure success:

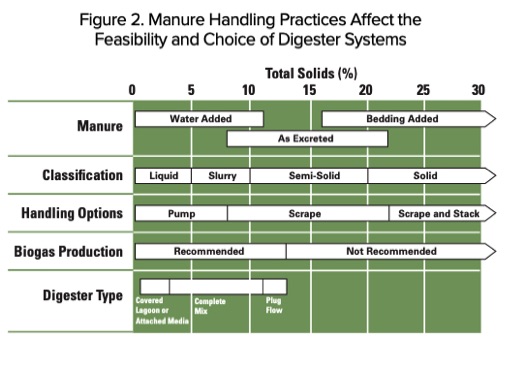

Preliminary screening of potential projects require that waste streams have total solids higher than 1.5%. In August of 2022 there were no known operating fixed film digesters (capable of handling dilute manure waste streams) that created adaquate methane production for commercial renewable energy credits. There is one plant under construction in Georgia as of September of 2022.

Confirmation of adequate biomass to produce the desired quantity and quality of methane

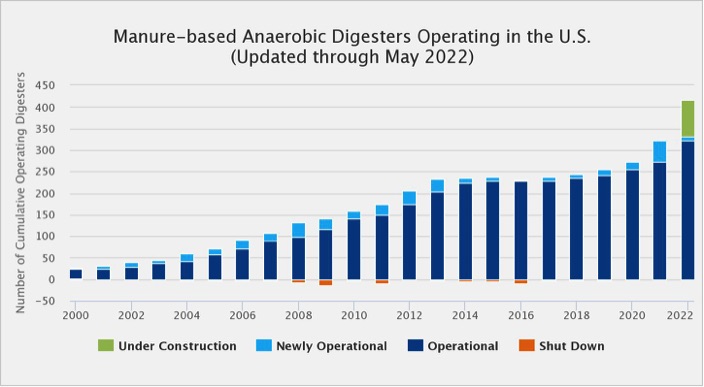

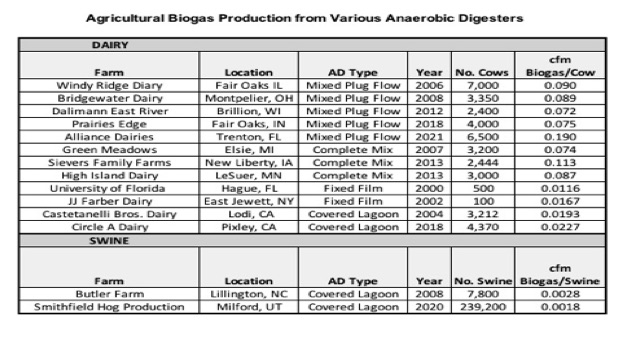

Theoretical methane production rates - Methane Produced = 242.7 mls CH4/gm of TVS added. Potential methane yields can also be estimated per animal ype in cfm/animal units.

Estimating Biogas Production Rates from Plant Performance Data

Soluble vs Solid Phase Methane Sources more

Methane production from biomass ADs increases with total solids concentrations up to 20%, then decreases. (Source: Effect of Solids Concentration in Cow Dung on Biogas Yield, Emmanuel, P. Makhura, et. al, 2019 7th International Renewable and Sustainable Energy Conference (IRSEC)). Higher solids concentrations combines soluble and insoluble organic biomass conversions to methane gas. 95% specific methane potential in both liquids and solids, 18% more in liquids than solids.

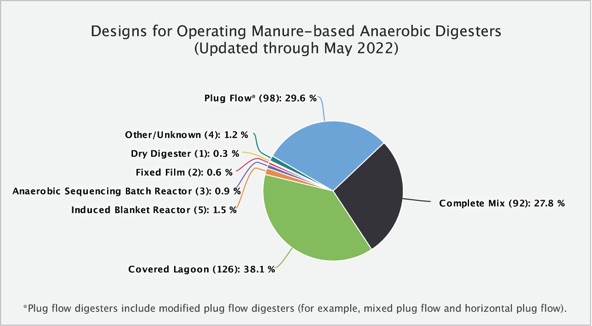

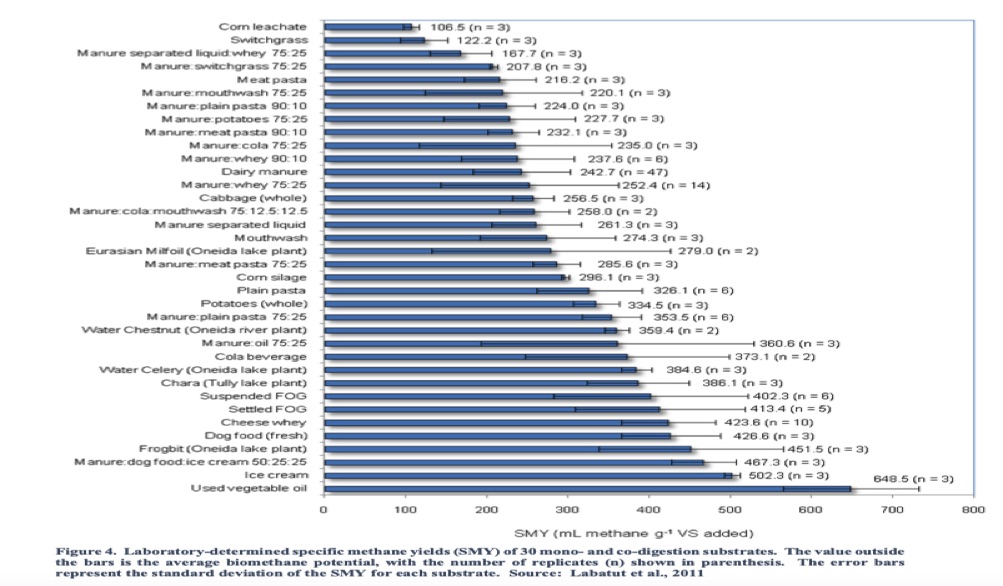

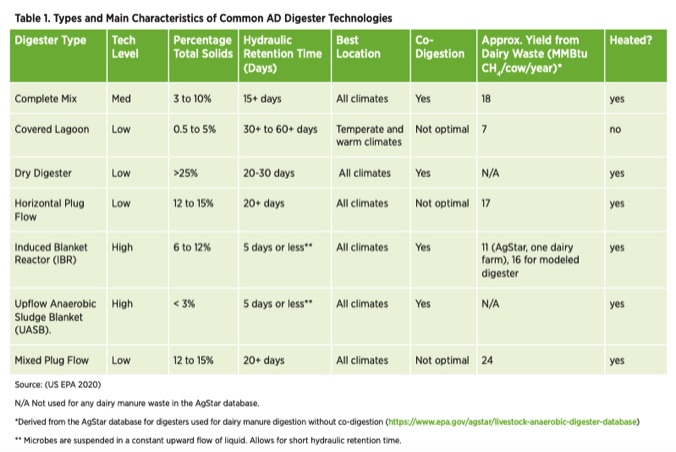

Digester Types - 95.5% or dairy manure anaerobic digesters are comprised of covered lagoons, complete mix, and plug flow reactors. There are only 2 fixed films reactors in operation as of May 2022 according to EPA's data base.

Covered Lagoons

Complete Mix

Plug Flow

Fixed Film

Anaerobic Digester Feedstock Waste Characterization

Toxic Materials in feed or Disinfection Processes

Critical waste stream characterizations

Bench-Scale Biomethant Production Tests

Coagulants - Alum increased potential specific CH4 methane yield by 15%

Kemira C557 1.8 mls in 1,000 mls barn flush water, detention time 40 minutes 400 mls solids, 73 minutes 275 mls solids, Kemira C573 and C581 less effective respectively. 2 mls of alum (35.74 Degrees Baume, 48.7% Sluminum Sulfate Solution, MC Chemicals) in 500 mls of barn flush, floc volume 150 mls, detention time 7 min.

Co-Digestion - In contrast, co-digestion typically uses organic waste material that retains higher energy content than manure, increasing biogas and methane production. Depending upon the type, concentration, and flow rate of the substrate used, biogas production can be enhanced by 25 to 400% (Alatriste-Mondragón et al. 2006; Braun et al. 2003; Frear et al. 2011).

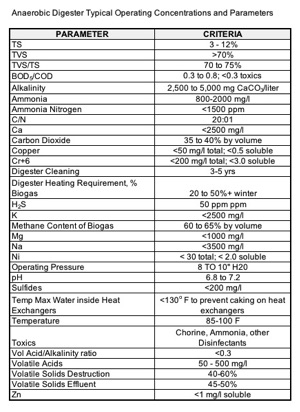

Digester Operational Parameters

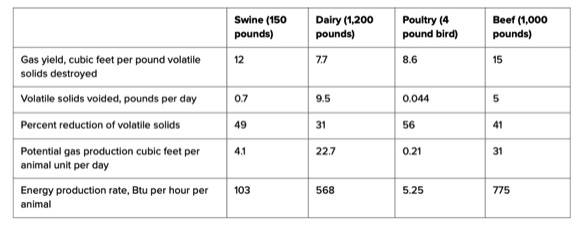

Heating requirements - Digesters may require 50% of biogas to heat digesters in winter, (366-CPS-1 UDSA reference).Typically, the Biogas is composed of about 60 percent methane and 40 percent carbon dioxide regardless of the type of waste. Pure methane has heat value of about 1,000 Btu per cubic foot, so we can expect the methane-carbon dioxide mixture to have a heat value of about 600 Btu per cubic foot. Heat value data for the various species on "per hour" basis is given in Table 1. Typically about one-third of the energy in the manure gas is needed to maintain the necessary 95 degree F temperature in the digester. Hence the energy available for other uses is two-thirds of the total energy produced. These values are listed in the last row of Table 1.Unless a substrate contains more than 60 percent or 70 percent VS on a dry mass basis, it is probably best to look for another candidate for digestion.

Costs - Average AD manure biogas yields of 20 to 30 cm /wet metric ton, is the minimum to just meet the required amount of biogas that is needed to offset capital costs and provide profitability (DEA 1995). Costs of installing a digester varies widely depending on the size, type, and operation. Typical capital costs for AD digester systems ranges from $1,000 to $2,000 per cow. Operating AD costs, are approximately $588,000 per year for a 2,000-cow dairy, or $294 per cow. (Source: 2018 Livesdtock and Poultry Environmental Learning Community article). For Mr. Williams Farms 1700 cows x $2000/cow = 3.4 MM for digester, O & M 0.5 MM/yr.

Predicting use of byproducts, sand recycling, fertilizers, water recycling for flush operations

Selecting the Digester type for maximum methane production

Optimization Techniques

Operational Strategies

Desirable Operation Feedstock Characterization for Digesters

TVS, TS, TVS/TS ratios, BOD/COD Ratios - Biological Oxygen Demand/Chemical Oxygen Demand (BOD/COD) ratios less than 0.3 indicates potential toxics present or insufficient organics present. Total volatile solids to total solids ratio range from 70 to 80%+.

Minimum Dairy size 5000+

Specific methane production rates from plug flow, then complete mix, least .....fixed film