Location: Atlanta, Georgia

Client: International Airport

Contract Amount: Confidential

PROBLEM

The drive train on a tanker carrying 10,000 gallons of Jet A

exploded and punctured the shell releasing 8,000 gallons of fuel

on a perimeter road at an International Airport. The site was

located in a restricted area in direct line with aircraft approach

runways.

Fuel was released on asphalt pavement and migrated overland

and 1-mile downstream into airport drainage ditches, tunnels, and

a creek. The airport authority required that a remedial approach

with minimal access and visual disturbances to approaching

aircraft be implemented.

AIRPORT JET FUEL REMEDIATION SOLUTION

Approximately 6,500 gallons of fuel were recovered from a one mile

section of stream utilizing skimmers, vacuum trucks, wash

down pumps, and a polypropylene rope mop.

An estimated 1,000 gallons of fuel saturated 600 cubic yards of

soils at the release point. 350 cubic yards of soils were

excavated from the bottom of the drainage ditch and placed on a

one foot deep biobed. Soils were cultivated with a disc/harrow.

The remaining 250 cubic yards of soil were treated in the bank

(insitu) employing three (3) horizontal aeration manifolds powered

by a regenerative blower. Ten (10) gallons of HC-2000 (diluted

with 16 volumes of water) were applied on a weekly basis to the

bank and bed bioremediation systems. A sprinkler system was

installed to maintain moisture levels at both locations.

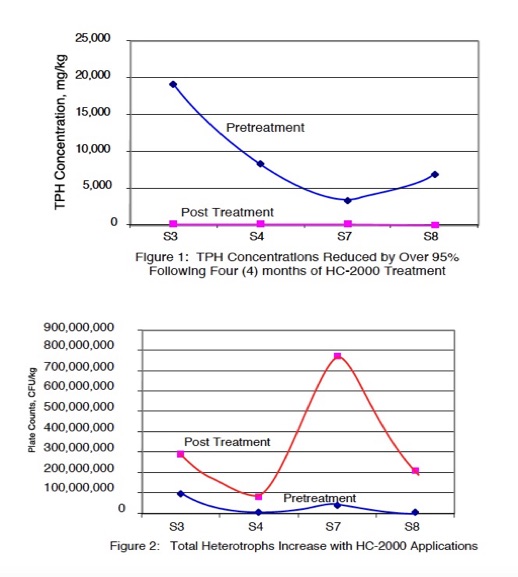

Total petroleum hydrocarbon (TPH) concentrations were reduced

below 200 mg/kg in 16 weeks (99% reduction). Total

heterotrophic plate counts were elevated from 6,000,000 to over

100,000,000 CFU/gm.

AIRPORT JET FUEL REMEDIATION COST/BENEFITS

Remtech trained airport personal to maintain the bioremediation

systems and reduce project costs. Remediating soils onsite with

HC-2000 minimized the number of site access and resident time

that met airport authority security and aircraft safety requirements.

HC-2000 Bioremediation Bed With Auto Sprinkler System

Transfer of Contaminated Soils to Biobed

HC-2000 Bank Bioremediation System