HC-2000 (HC2) is bioremediation agent and a Green Sustainable Technology.

Remtech has developed a proprietary slow-release enhanced bioremediation agent and biosurfactant product, HC-2000 (HC2), that cleans, disinfects, desorbs, reduces odors and degrades fuels and sheens, oils, transformer oils, lubricants, chlorinated and non-chlorinated solvents. HC-2000 biostimulation agent works on soil, ballast, gravel, groundwater, surface water, wastewater, sludges, septic tanks, power substations, cleaning surfaces (clothing, concrete, asphalt, metal), and other matrices. Biosurfactants increase mass transfer of biochemical reaction accelerators to rapidly degrade and clean petroleum based contaminates. Slow release ingredients continue to deliver active ingredients over periods exceeding 1 year.

HC-2000 in a Green Sustainable Technology product that restores the environment by accelerating natural native systems (heterotrophic bacteria) to degrade petroleum and solvent based contaminants. HC-2000 removes toxic contaminants with minimal economic disruptions to business and generally cost less than other remedial technologies. Remtech's Bioremediation Design Optimization Primer with HC-2000 is presented here. Remtech's Biopile Bioremediation Design Optimization Primer with HC-2000 is presented here.

HC-2000 has been used successfully on over 400 site remediation during the past 17 years. HC2 is approved by Georgia & Florida for soil and groundwater cleanups. Other states and regulatory authorities typically rapidly approve HC-2000 on a case-by-case basis.

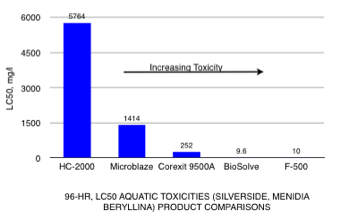

HC-2000 is a bioremediation agent for oil spills, petroleum, contaminated soil, contaminated groundwater, fuel and solvents. HC-2000's biodegradation product efficacy (degradation efficiency) and lower toxicity surpasses commercial fertilizers, Micro-blaze, Fuel Buster (F-500), BioSolve, and the majority of products on EPA’s National Contingency Plan List. HC2 is designed to work on inland freshwater applications and refined fuels, oils, and solvents that are not addressed by EPA’s NCP list of saltwater approved crude oil remediation and cleaning products.

HC-2000 Bioremediation Product Applications

• Soil, Railroad Ballast, Gravel Remediation at Power Plants,

Substations and AST Tank Farms without Disturbing Grounding Grids

• Groundwater & Surfacewater Remediations

• Wastewater Treatment Enhancement

• Oil Sheen Removal

• Vapor and Odor Control

• Pavement & Surface (concrete, asphalt, metal) Cleaning

• Solids & Sludge Breakup

• Forrest Canopy & Vegetation Cleaning

• Tank Cleaning

• Spill Cleanups

Technical Publications Available

• HC-2000 Biodegradation & Cleaning Applications on Petroleum

Hydrocarbon & Solvent Cleanups

• HC-2000 Petroleum Hydrocarbon Efficacy & Aquatic Toxicity Testing

in Freshwater & Soil Environments

• HC-2000 Range Finding Aquatic Toxicities

• HC-2000 Bioremediation of Petroleum Hydrocarbon Spills on

Featured HC-2000 Bioremediation Agent Projects

Gasoline Remediation in Wetland

Gasoline UST Site Biosparge Remediation

Solvent Site Biosparge Remediation

Diesel UST Site Total Fluids/HC2000 Remediation

Diesel Spill Ballast Bioremediation

Substation Transformer Oil Bioremediation with HC2000

HC-2000 Diesel Spill Bioremediation around 100-year old Fragile Water Main

BIOREMEDIATION, BIOSTIMULATION, BIOSURFACTANT AGENT FOR OIL SPILLS, CONTAMINATED SOIL, GROUNDWATER, PETROLEUM, WASTEWATER, HC-2000

Transformer Explosion at Substation - Surface Oil and Saturated Soils Above Grounding Grid Excavated

Removing Mineral Oil Sheens from Power Plant Detention Pond with HC-2000

Cleaning Oil Stains from Asphalt with HC-2000 and Surface Washer

Cleaning Oil Stains from Concrete with HC-2000 and Broom or Power Broom

Oil Stains on Concrete Pavement Prior to Cleaning

Concrete Pavement Cleaned with HC-2000 & Power Broom

Cleaned Pavement

** CDFW-OSPR - Prohibited in California

(LC50’s < 10 mg/l)

Dec, 2016